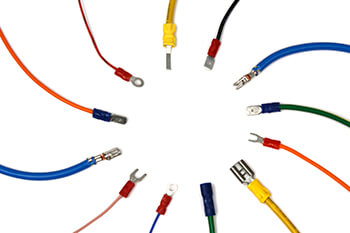

Crimp terminal, wire connector, electrical connector, cable lug, cable terminal, wire terminal etc., is widely use is various industry. The quality of a crimp joint depends on the strength of the joint as well as its electrical conductivity. Crimp joint testing can ensure the integrity of the final product. In general, wire connection lug testing can be broken into two categories; destructive pull testing and non-destructive pull testing. These tests both aim to determine a tensile force that the test wire can withstand. To meet the requirements of standard specifications, the tensile force that a wire can withstand must be greater than the minimum tensile strength defined by the standard.

Related standard:

ASTM B913: Standard Test Method for Evaluation of Crimped Electrical Connections to 16-Gauge and Smaller Diameter Stranded and Solid Conductors.

ISO 1966: Crimped joints for aircraft electrical cables

ASTM F458: Standard Practice for Nondestructive Pull Testing of Wire Bonds1,2

EIA 364-08B: Crimp Tensile Strength Test Procedure for Electrical Connectors.

SAE/AS 7928: Terminal, Lug, Splice, and Crimp Copper Strength Specifications.

Global links

Global links