- Universal testing machine

- Fixtures

- Medical/Biomedical device testing

- Vehicles (car, motorcycle)

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

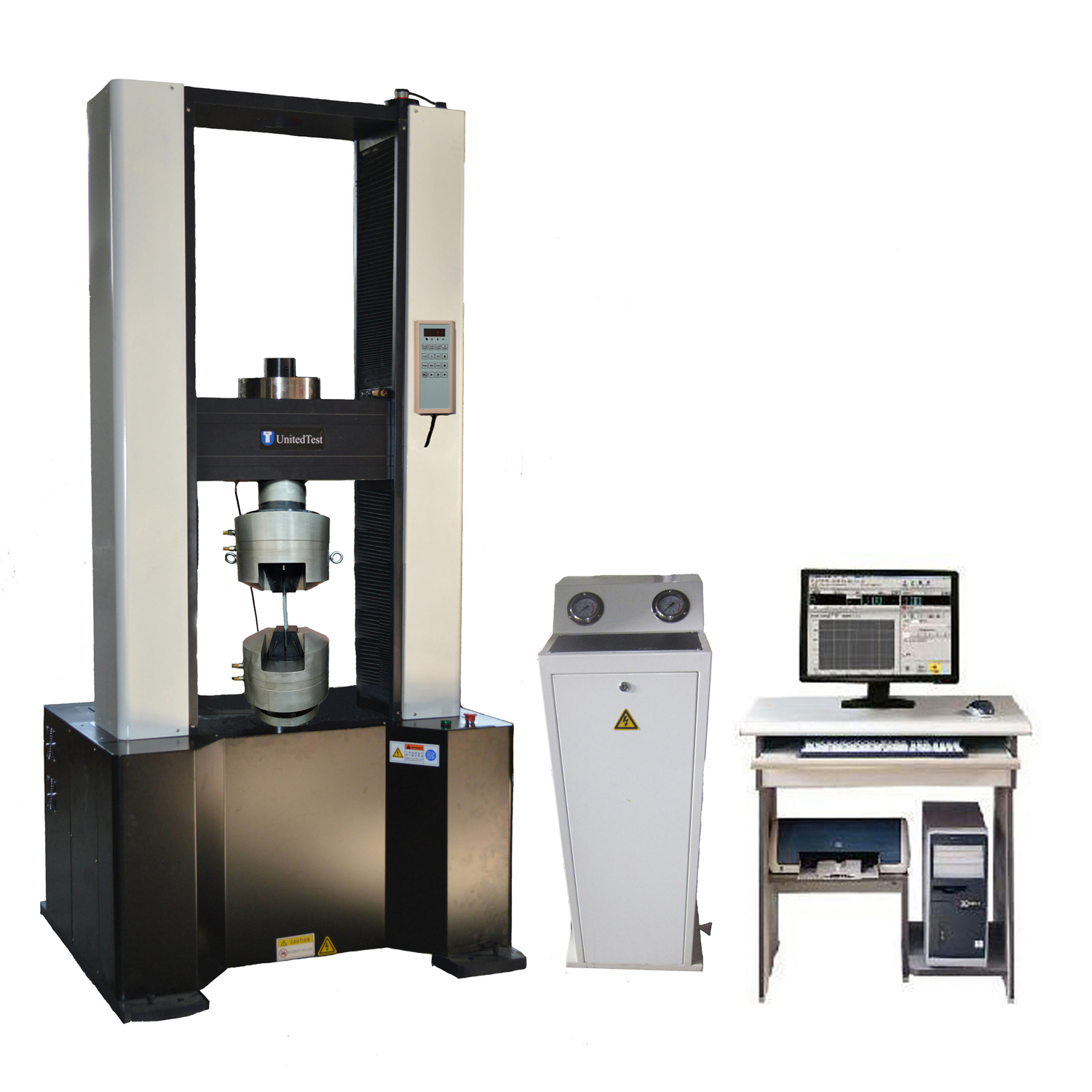

These models are robust, heavy-duty frames commonly used for testing high-strength metals and alloys, advanced composites, aerospace and automotive structures, bolts, fasteners, and plate steels. Frames are available in load capacities of 400kN, 500Kn, 600KN, 1000KN; and several variations are available to accommodate requirements for both extended travel and extra wide test space.

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO 7500-1.

Main application:

Applications solutions include medical devices, biomaterials, textiles, elastomers, food, small components, wire, paper, plastic, film, fibers and threads, adhesives and many more.

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Comply with different standards such as ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

| Load capacity | 500KN/600KN |

| Multiple load cell in one machine function | YES |

| Load Accuracy | Class 1/0.5 according ISO7500-1 |

| Load cell overload capacity | 150% of rate capacity |

| Load measuring resolution | 1/500000 FS, stepless |

| Position / displacement resolution | 0.001mm |

| Crosshead travel | 1100mm |

| Tensile test space | 600mm |

| Compression test space | 700mm |

| Effective testing width (Clearance between columns) | 600mm |

| Standard tensile test fixture | Automatic hydraulic type translational moving grip |

| Wedge tensile fixture Flat specimen range | 0-40mm |

| Wedge tensile fixture Flat specimen range | Φ20-Φ50mm |

| Compression platen diameter | Φ150mm |

| Testing speed range | 0.05 mm/min~300 mm/min, stepless, adjustable arbitrarily |

| Weight | 1300Kg |

| Dimensions | 1200*1050*2550mm |

| Standard Power | 380/220V, 50/60HZ, 3 phase, 4Kw |

| Analysis software | SmartTest English version |

| Working system | MS Win7 / Win10 |

| Frame structure | Standard: Single test space |

| High Stiffness Frame | 1 set |

| Servo driving system: Servo motor: | 1 set |

| Loadcell: | 1 set |

| Decelerator and deceleration system | 1 set |

| Leading screw: | 1 set |

| Wedge Tensile test fixture | 1 set |

| Compression test fixture(Φ100mm) | 1 set |

| Bending test fixture | 1 set |

| Professional testing software(SmartTest, English version) | 1 set |

| Computer | 1 set |

| Printer | 1 set |

| Documents (Manual, packing list, certificate) | |

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO 7500-1.

Test method standard like: ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

Global links

Global links