ASTM D6110 - 10

Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics

This test method is used to determine the resistance of plastics to breakage by flexural shock as indicated by the energy extracted from standardized pendulum-type hammers, mounted in standardized machines, in breaking standard specimens with one pendulum swing. This test method requires specimens to be made with a milled notch. The notch produces a stress concentration which promotes a brittle, rather than a ductile, fracture. The results of this test method are reported in terms of energy absorbed per unit of specimen width.

The tests require specimens made with a milled notch, hence the test is often referred to as the “notched bar impact test”. In both the Charpy and Izod Tests, the notch produces a stress concentration which promotes a brittle, rather than a ductile, fracture.

The results are reported in terms of energy absorbed per unit of specimen width, or more specifically, the energy absorbed in breaking the specimen which is equal to the difference between the potential energy at the moment of impact and the residual energy.

| Recommend test machine | |

|

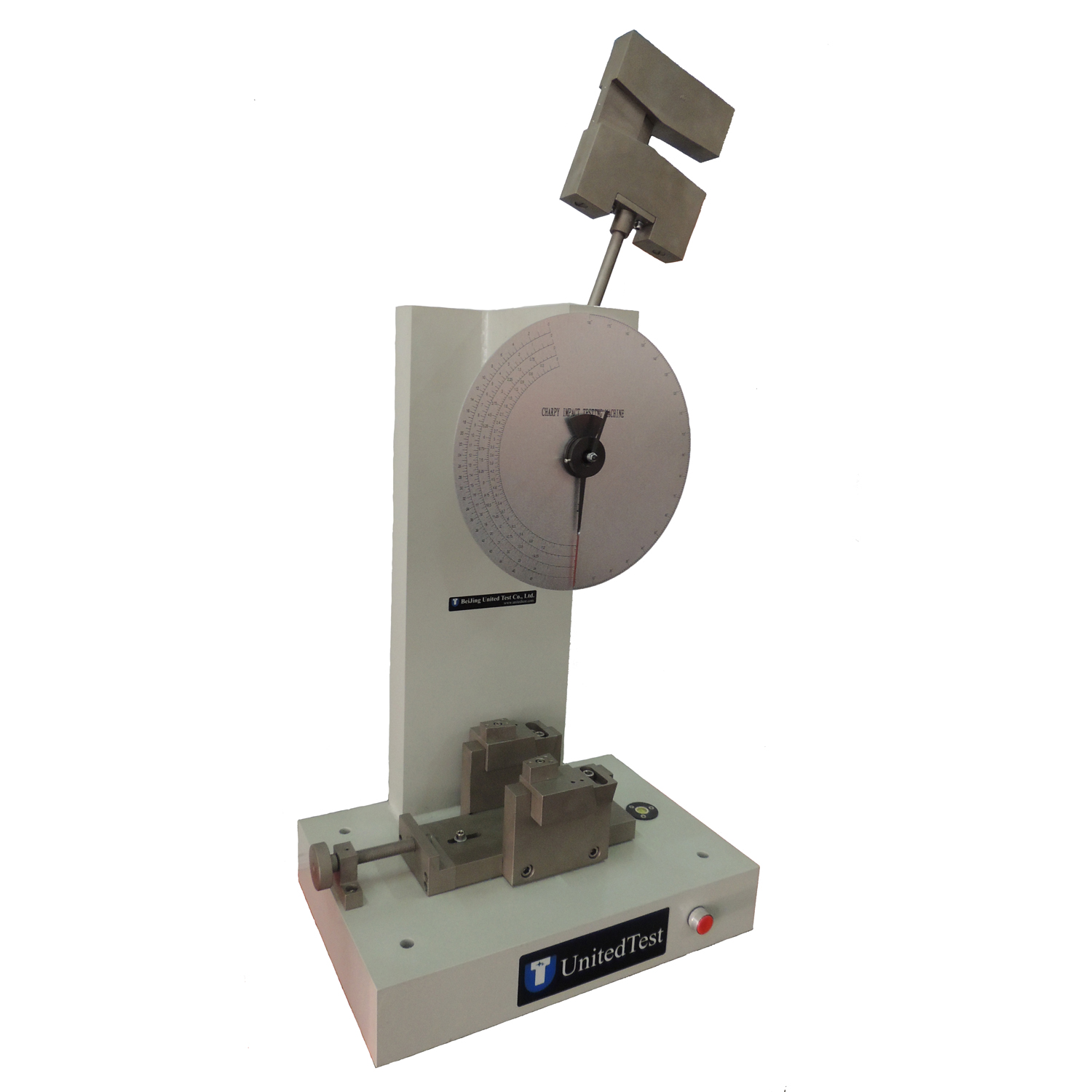

XJJ-5/50 Charpy impact tester 1, Dial display, Charpy test method; 2, This economical model is simple in structure, easy to operate. 3, Support vice, pendulum is nickel coating, good appearance and anti-corrosion. 4, Energy range: 1J, 2J, 5J, 15J, 50J. |

|

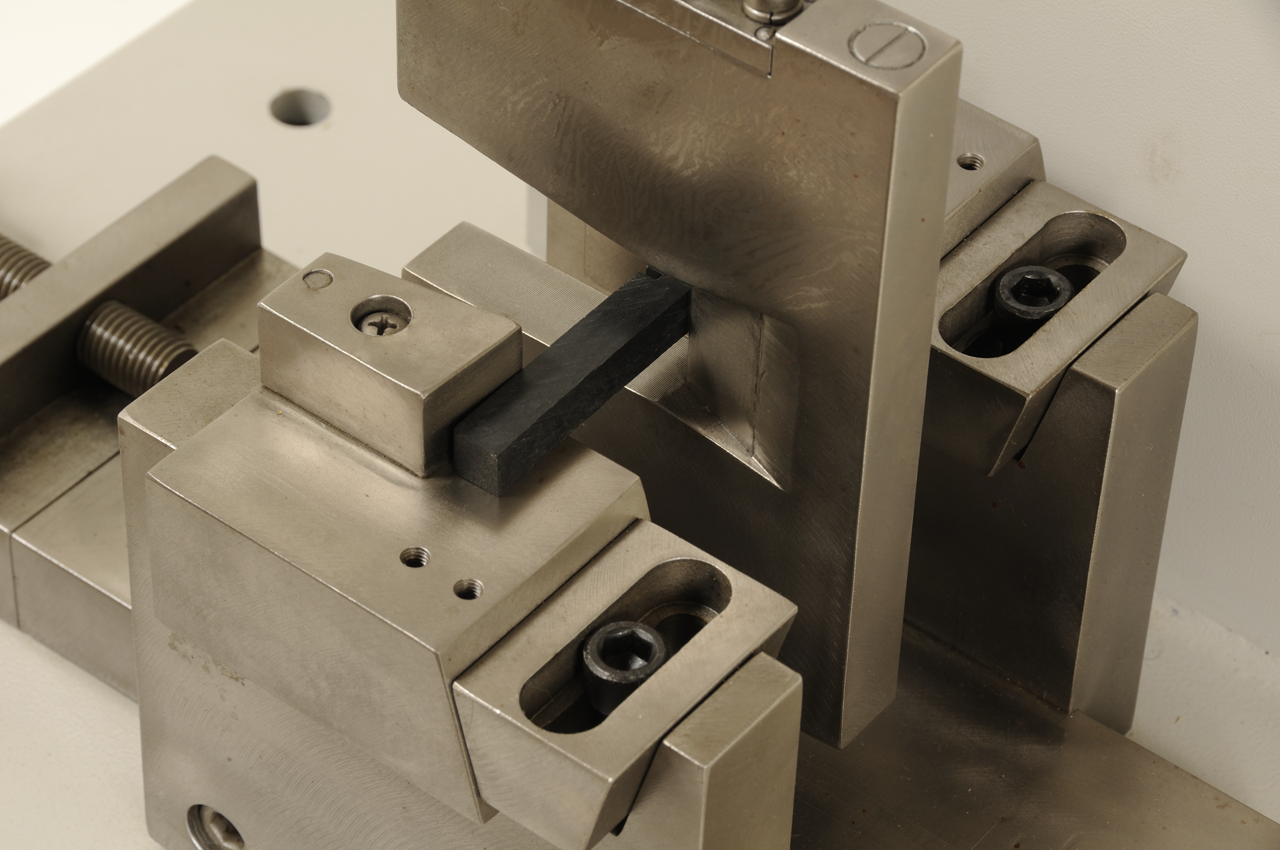

Impact specimen notching machine Sample preparation machine for impact tester is used to process the non-metal material impact test specimen, make the notch then do impact test. Such as the plastics, organic glass etc., |

Or refer product link:

plastic charpy Impact testing machine;

plastic specimen notch making machine.

Global links

Global links