Vicat softening temperature or Vicat hardness is the determination of the softening point for materials that have no definite melting point, such as plastics. It is taken as the temperature at which the specimen is penetrated to a depth of 1 mm by a flat-ended needle with a 1 mm2 circular or square cross-section. For the Vicat A test, a load of 10 N is used. For the Vicat B test, the load is 50 N.

Standards to determine Vicat softening point include ASTM D 1525 and ISO 306, which are largely equivalent.

The vicat softening temperature can be used to compare the heat-characteristics of different materials.

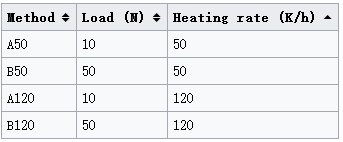

Four different methods of vicat test may be used for testing.

VICAT TEST METHODS

Scope:

The Vicat softening temperature is the temperature at which a flat-ended needle penetrates the specimen to the depth of 1 mm under a specific load. The temperature reflects the point of softening to be expected when a material is used in an elevated temperature application.

Test Procedure:

A test specimen is placed in the testing apparatus so that the penetrating needle rests on its surface at least 1 mm from the edge. A load of 10N or 50N is applied to the specimen. The specimen is then lowered into an oil bath at 23 degrees C. The bath is raised at a rate of 50° or 120° C per hour until the needle penetrates 1 mm.

Specimen Size:

The test specimen must be between 3 and 6.5 mm thick and at least 10 mm in width and length. No more than three layers may be stacked to achieve minimum thickness.

Data:

The Vicat softening test determines the temperature at which the needle penetrates 1 mm.

| Recommend test machine | |

HVT series HDT/VICAT tester | |