ISO 6892 specifies the method for tensile testing of metallic materials and defines the mechanical properties which can be determined at room temperature. Related standard ASTM E8 , JIS Z2241 Method of tensile test for metallic materials.

The robust load-frame features four hard-chromed guide-columns and massive base and moving crossheads, ensuring excellent guidance properties and a high level of machine stiffness.

Maintenance-free digitally controlled AC drive technology combined with an innovative motor Feedback system allows excellent constant speed characteristics to be achieved even at extremely low speeds.

The backlash-free pre-stressed precision ball-screws with digitally controlled AC servo drive allow virtually maintenance-free operation.

The large test area combined with low overall height enables specimens and components with a wide range of lengths to be tested.

In accordance with this standard to test include metallic sheets and plates, wire, bar or section, rebar, and tubes. Specimens need to be gripped securely ensuring axial alignment in order to minimize bending. The specimen is then strained in tension until failure using either Method A1/A2 or Method B control modes. During this time, the load, crosshead extension, time, and strain data are recorded to determine the material characteristics. The typical calculations include: Yield Point (Rp, Reh, Rel), Ultimate Tensile Stress (Rm), and specific strain values at calculations (A, Agt etc.).

ISO 6892-1 also specifies the specimen geometries that should be used depending on the type of product that is being tested.

ISO 6892-1 Method A - Tensile Test on Metals; ISO 6892-1 metal tensile tesing machine.

In 2009, ISO 6892-1 introduced Method A, the method of test control based on maintaining a strain rate. The more traditional method, now known as Method B, was based on maintaining a stress rate during the elastic region of tensile test. There could be confusion around the introduction of Method A. Many understood this as only being achievable using equipment capable of closed-loop strain control, but this is not true. It is possible to conform to Method A using a constant crosshead separation rate.

Tensile specimens made from metal. The left two specimens have a round cross-section and threaded shoulders. The right two are flat specimens designed to be used with serrated grips.

| Recommend test machine | |

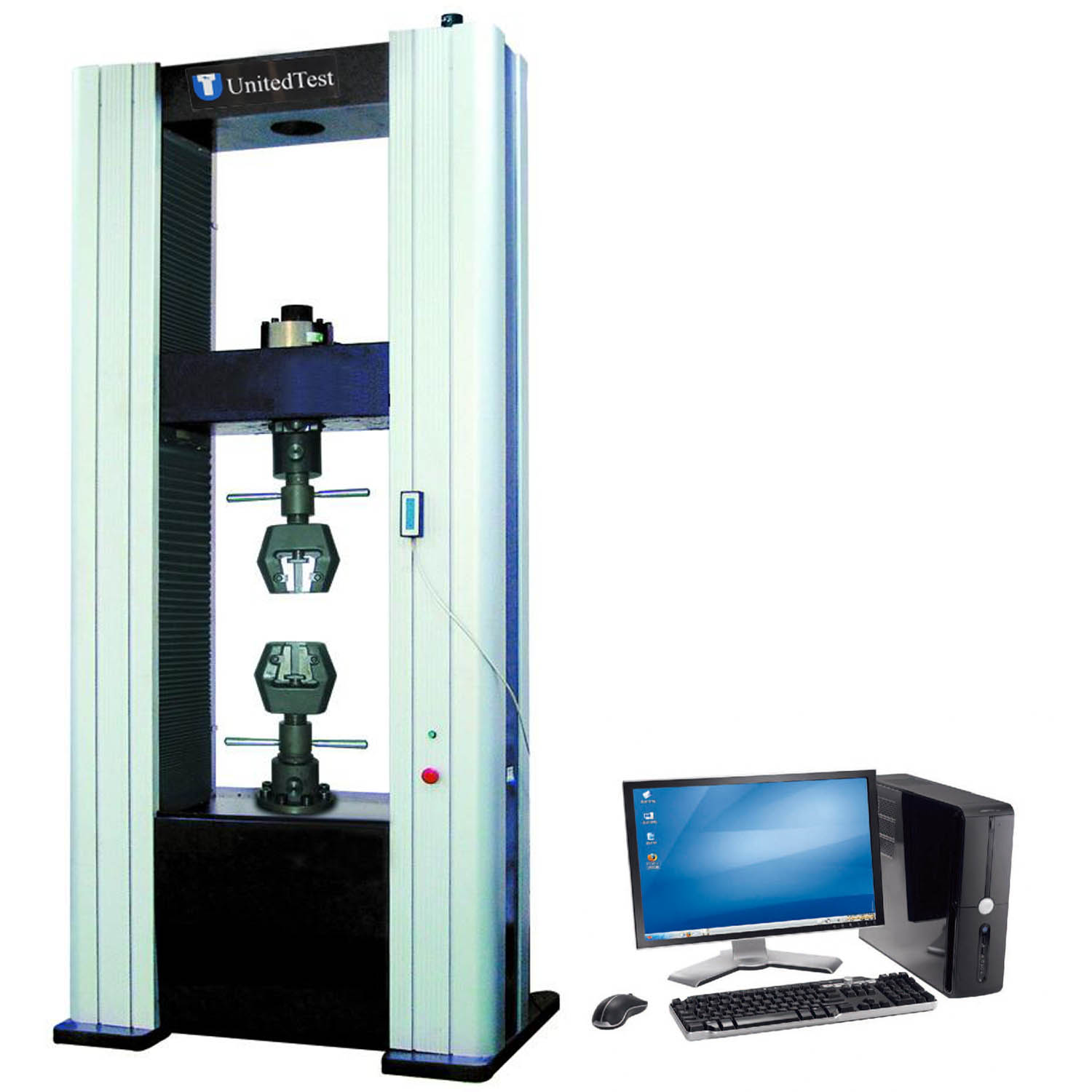

Electronic ISO 6892 tensile test machine Universal Testing Machine | |

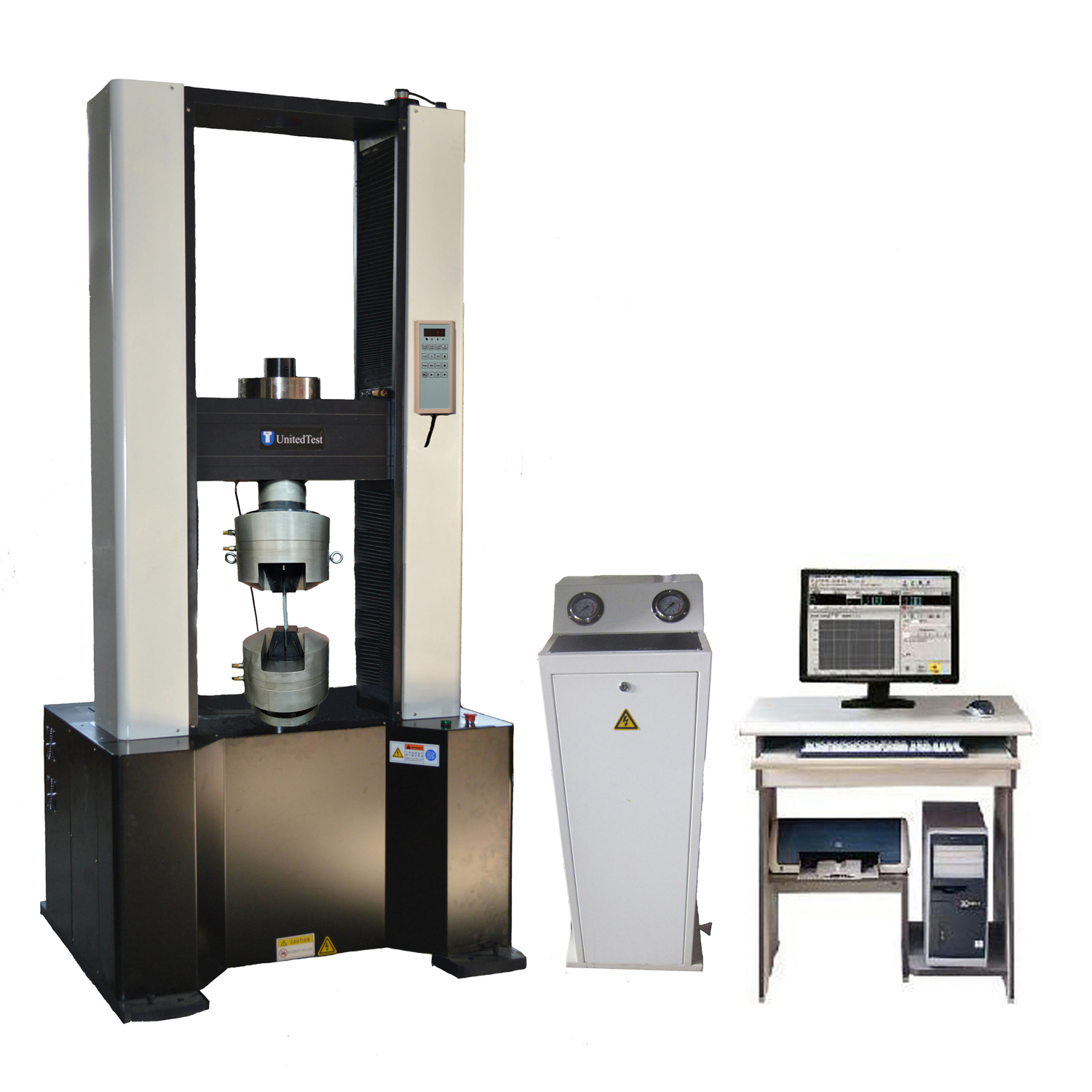

| Hydraulic ISO 6892-1 material tensile testing machine Universal Testing Machine 1, Load range 300 ~ 3000KN; 2, Digital display, Hydraulic servo, Computer display manual control; 3, Compression, tension, flexural test fixture. 4, Load, deformation, elongation, elastic modulus etc., |

Global links

Global links