- Universal testing machine

- Fixtures

- Medical/Biomedical device

- Vehicles motorcycle

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

The Brinell Hardness tester that shows the largest indentation among all the hardness tests is able to reflect the comprehensive features of the material ,and the test is unaffected by the organization microscopic segregation and the compositional unevenness of the specimen; and hence it is a hardness testing with high precision.

Principle:

All Brinell tests use a carbide ball indenter. The test procedure is as follows:

? The indenter is pressed into the sample by an accurately controlled test force.

? The force is maintained for a specific dwell time, normally 10-15 seconds.

? After the dwell time is complete, the indenter is removed leaving a round indent in the sample.

? The size of the indent is determined optically by measuring two diagonals of the round indent using either a portable microscope or one that is integrated with the load application device.

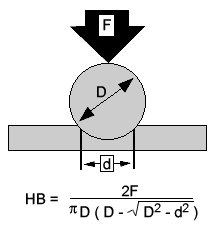

Test Method Illustration

D = Ball diameter

d = impression diameter

F = load

HB = Brinell result

? The Brinell hardness number is a function of the test force divided by the curved surface area of the indent. The indentation is considered to be spherical with a radius equal to half the diameter of the ball. The average of the two diagonals is used in the above formula to calculate the Brinell hardness.

Features:

1), Unified product combining the precise mechanical structure with the computer control by means of the mechanical and electrical circuit system;

2), Adopts the motorized test force application without weight blocks.

3), Uses 0.5‰ accuracy compression sensor to feedback the information and the CPU control system to automatically compensate the test force lost during the testing;

4), The test force and the load dwell time can be directly set pressing the selected keys on the touch-keyboard, with reliable repetition, precise reading and easy operation.

| MODEL | HBE-3000A | |

| Test force | N | 612.9, 9 80, 1226, 1839, 2452, 4903, 7355, 9807, 14710, 29420 |

| Kg | 62.5, 100, 125, 187.5, 250, 500, 750,1000, 1500, 3000 | |

| Testing range | (8-650)HBW | |

| Accuracy of indication value | ||

| HBW≤125 | Max. indication tolerance: ±3.0, repetition: ≤3.5 | |

| 125<hbw≤225< strong=""> | Max. indication tolerance: ±2.5, repetition: ≤3.0 | |

| HBW>225 | Max. indication tolerance: ±2.0, repetition: ≤2.5 | |

| Max. height of test specimen | 220mm | |

| Max. width of test specimen | 130mm | |

| Amplification of Microscope | 20* | |

| Min Reading Grade of the Drum wheel of the microscope | 0.005mm | |

| Power | AC 220V, 50/60HZ | |

| Net Weight | 125Kg | |

| Standard Accessories | Standard Rockwell hardness block: 2 pcs; 20* microscope; steel ball indenter: (∮2.5mm, ∮5mm, ∮10mm); Test Tables: (Large, Small and V-shaped); Power cord, manual, etc. | |

Standard Rockwell hardness block: 2 pcs;

20* microscope;

steel ball indenter: (∮2.5mm, ∮5mm, ∮10mm);

Test Tables: (Large, Small and V-shaped);

Power cord, manual, etc.

ASTM E10 “Standard Test Method for Brinell Hardness of Metallic Materials”

ISO 6506 “Metallic materials -- Brinell hardness test”

Global links

Global links