- Universal testing machine

- Fixtures

- Medical/Biomedical device

- Vehicles motorcycle

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

Torsion tests twist a material or test component to a specified degree, with a specified force, or until the material fails in torsion. The twisting force of a torsion test is applied to the test sample by anchoring one end so that it cannot move or rotate and applying a moment to the other end so that the sample is rotated about its axis. The rotating moment may also be applied to both ends of the sample but the ends must be rotated in opposite directions. The forces and mechanics found in this test are similar to those found in a piece of string that has one end held in a hand and the other end twisted by the other.

Purpose of torsion testing:

The purpose of a torsion test is to determine the behavior a material or test sample exhibits when twisted or under torsional forces as a result of applied moments that cause shear stress about the axis. Measurable values include: the modulus of elasticity in shear, yield shear strength, torsional fatigue life, ductility, ultimate shear strength, and modulus of rupture in shear. These values are similar but not the same as those measured by a tensile test and are important in manufacturing as they may be used to simulate the service conditions, check the product’s quality and design, and ensure that it was manufactured correctly.

Types of torsion tests:

The three common forms that torsion testing take include failure, proof and operational. A torsion test for failure requires that the test sample be twisted until it breaks and is designed to measure the strength of the sample. A proof test is designed to observe the material under a specified torque load over a set period of time. Finally, operational testing is measures the material’s performance under the expected service conditions of its application. All of these forms of tests may be performed with either torsion only loading or a combination of torsion and axial (tension or compression) loading depending upon the characteristics to be measured.

Types of materials:

Many materials experience torques or torsional forces in their applications and so will benefit from or require torsion testing. Materials used in structural, biomedical and automotive applications are among the more common materials to experience torsion in their applications. These materials may be composed of metals, plastics, woods, polymers, composites, or ceramics among others and commonly take the forms of fasteners, rods, beams, tubes and wires.

Features:

1), Adopt servo control system, through the servo to control motor, cycloidal pin gear speed reducer drive the active chuck rotate;

2), High precision torsion sensor to measure the sample torque;

3), Photoelectric encoder to measure torsion angle;

4), Computer display test result,

5), With high stiffness and high endurance straight guide rail.

6), Controller can adjust sampling rate, at material yield stage can use high sampling rate;

7), Software can divide three level management, different level has different limit of authority;

8), Main test software operation, function, curve, data real time display on the main window, easy operation, can display torque-torsion angle, torque-corner, torque-time, torsion angle-time etc. curve;

9), Software can calculate and analysis shear modulus G, provision non-proportional torsion strengthτP0.015 and τP0.3, upper torsion yield strength τSu, lower torsion yield strength τSl, torsion strength τb, max. non-proportional shearing strainγ max.;

10), Can turn positive and negative two directions, after test finish, automatically or manually return to test original position.

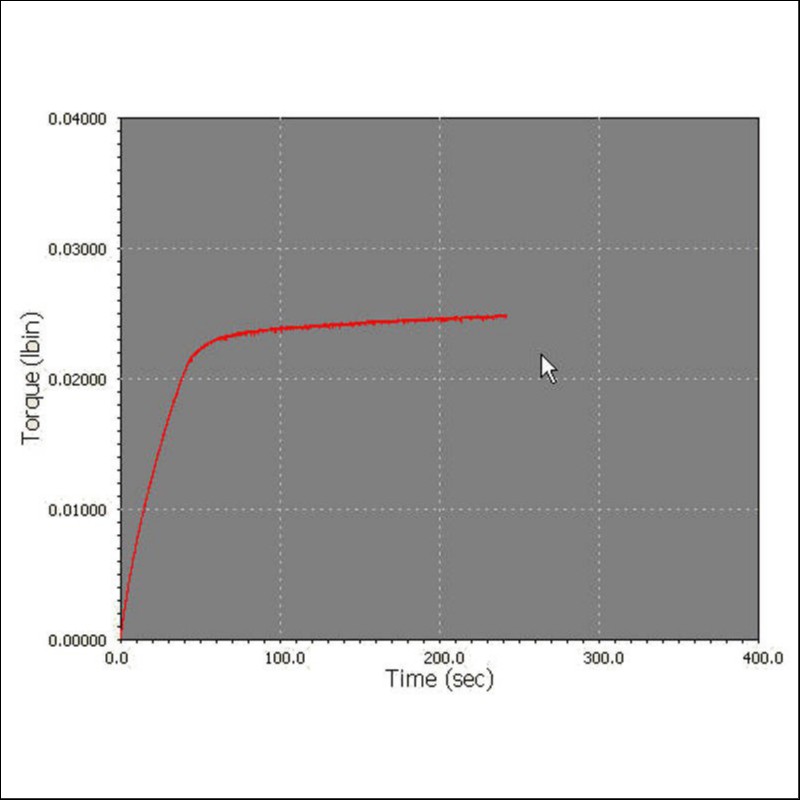

Typical steel wire torsion test diagram

| Model | NJW-5 NJW-10 NJW-20 | NJW-50 NJW-100 NJW-200 | |

| Max. torque | 5N.m 10N.m 20N.m | 50N.m 100N.m 200N.m | |

| Torque measuring range | 2%---100% F.S | ||

| Torque indication accuracy | ±1% | ||

| Torque resolution | 0.01N.m | ||

| Torsion angle Min. reading | 0.1? | ||

| Max. torque angle | 9999.9? | ||

| Effective test space | 0~260mm (customized available) | ||

| Dimensions | 920*300*300mm | 950*330*400mm | |

| Power supply | 50Hz, 220V, Single phase | ||

| Weight | 100Kg | 130Kg | |

| Model | NJW-500 | NJW-1000 | NJW-2000 | NJW-3000 | NJW-5000 |

| Max. torque | 500N.m | 1000N.m | 2000N.m | 3000N.m | 5000N.m |

| Torque measuring range | 2%---100% F.S | ||||

| Torque indication accuracy | ±1% | ||||

| Torque resolution | ±1/300000 | ||||

| Torsion angle measuring error | ±1% | ||||

| Torsion angle Min. reading | 0.01? | ||||

| Effective test space | 0~500mm (customized available) | ||||

| Dimensions | 1650*450*1120mm | 1750*550*1250mm | |||

| Power supply | 50Hz, 220V, Single phase | ||||

| Weight | 600Kg | 800Kg | 1000Kg | ||

Frame

Computer

Servo Motor

Torque Sensor (5~200N.m)

Optical Displacement Sensor

Power Lines

Chuck

Operation Manual

ISO 7800: Metallic materials -- Wire -- Simple torsion test

ISO 6475: Implants for surgery -- Metal bone screws with asymmetrical thread and spherical under-surface -- Mechanical requirements and test methods.

ASTM F543: Standard Specification and Test Methods for Metallic Medical Bone Screws

ASTM F383 Static Bend and Torsion Testing of Intramedullary Rods

ASTM E2207 Axial-Torsional Fatigue Thin-Walled Tubular Materials Test Equipment

ASTM D5279 Thermoset & Thermoplastic Dynamic Torsion Testing Machine

ASTM D1043 Torsion Plastics Test Equipment

ASTM A938 Torsional Test of Wire

Global links

Global links