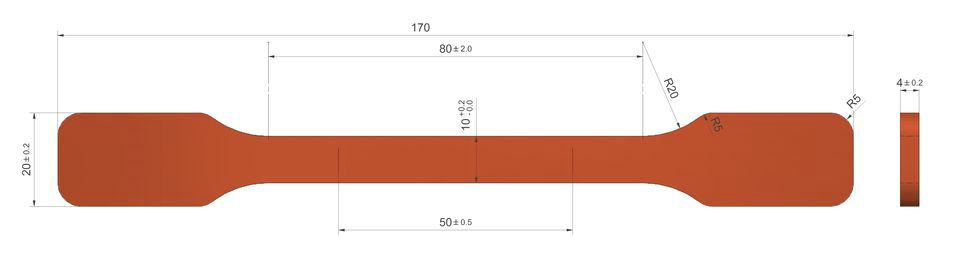

ISO 527-2 Tensile Test of Moulding and Extrusion Plastics

ISO 527-2 specifies the test conditions for determining the tensile properties of moulding and extrusion plastics, based upon the general principles given in ISO 527-1.

ISO 527-1/-ISO 527-2 and ASTM D 638 both specify tensile test methods. The two standards are technically equivalent but do not provide completely comparable results, as specimen shapes, test speeds and method of result determination differ in some respects.

ISO 527-2 specifies the test conditions for determining the tensile properties of moulding and extrusion plastics, based upon the general principles given in ISO 527-1.The methods described in ISO 527-2 are selectively suitable for use with the following range of materials: rigid and semi-rigid thermoplastics moulding, extrusion and cast materials, including compounds filled and reinforced by, for example, short fibres, small rods, plates or granules but excluding textile fibres (see ISO 527-4 and ISO 527-5).

See ISO 527-1:2012, Clause 3 for the definition of "rigid" and "semi-rigid". Rigid and semi-rigid thermosetting moulding and cast materials, including filled and reinforced compounds but excluding textile fibres as reinforcement (see ISO 527-4 and ISO 527-5); thermotropic liquid crystal polymers. ISO 527-1 requires a universal test machine configured for tensile-testing with testing speeds of 1-500 mm/min.

The following calculations can be made from tensile test results:

*Tensile strength (at yield and at break)

*Tensile modulus

*Strain

*Elongation and percent elongation at yield

*Elongation and percent elongation at break.

It cover a range of plastics including thermosets, thermoplastics, and fiber-reinforced plastics. Test specimens may be rigid, semi-rigid, molded or extruded plastics, and are commonly in the shape of a dumbbell or dog bone.

The mechanical properties of plastics vary depending on the type of plastic, as well as the additives that may be incorporated into the formulation. Properties, such as strength, ductility and toughness, are influenced by different types of additives. To determine the appropriate testing equipment, it is important to understand how material behavior changes as a result of the various additives.

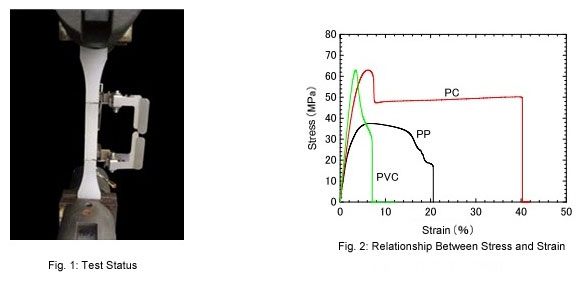

Refer UnitedTest electronic universal testing machine, load range 100N ~ 50Kn. With pneumatic side-action grips, Wedge grips and manual screw action grips are also suitable. The choice of jaw faces may vary depending on sample and material type, but serrated faces are most common.

Global links

Global links