- Universal testing machine

- Fixtures

- Medical/Biomedical device

- Vehicles motorcycle

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Spring testing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

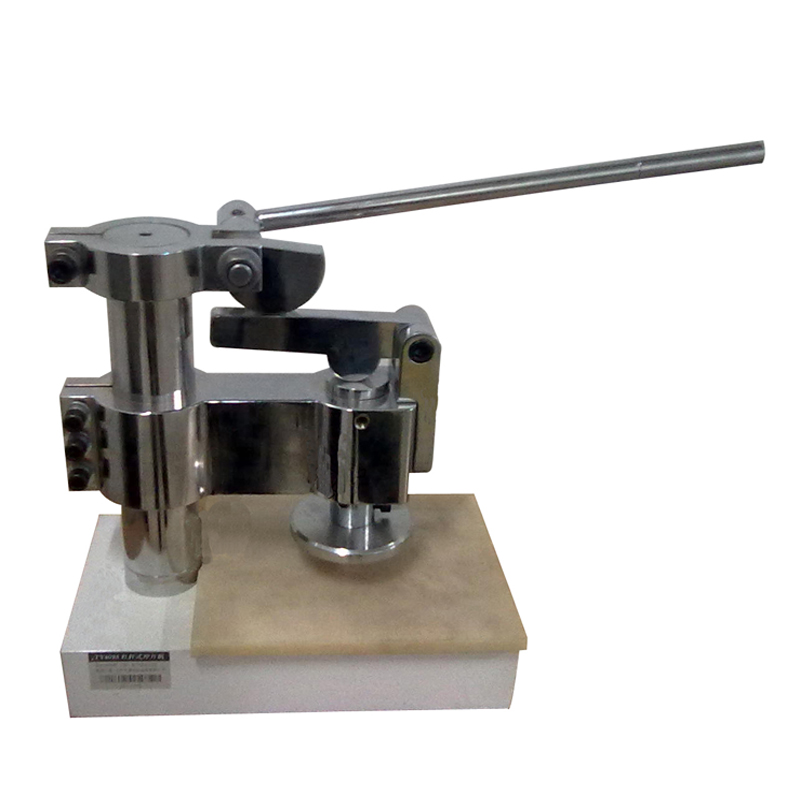

Dial Charpy Impact Tester ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values obtained can be used for quality control or to differentiate general toughness.

United Test product both the IZOD and Charpy impact tester, in dial display, LCD screen display and computer control used determine the impact ductility of nonmetallic materials, such as Rigid thermoplastic and thermosetting plastic, thermosetting plastic and thermoplastic after fiber-reinforced. It is widely used in the industries of plastic products, plastic manufacture, petro chemical etc, University, scientific research institute and commodity inspection department.

Charpy Test: The specimen is mounted horizontally and supported unclamped at both ends. The hammer is released and allowed to strike through the specimen. If breakage does not occur, a heavier hammer is used until failure occurs.

IZOD Test: The specimen is clamped into the pendulum impact test fixture with the notched side facing the striking edge of the pendulum. The pendulum is released and allowed to strike through the specimen. If breakage does not occur, a heavier hammer is used until failure occurs. Since many materials (especially thermoplastics) exhibit lower impact strength at reduced temperatures, it is sometimes appropriate to test materials at temperatures that simulate the intended end use environment.

Feature of XJJ series Charpy pendulum impact testing machine:

1, Dial display, Charpy test method;

2, This economical model is simple in structure, easy to operate.

3, Support vice, pendulum is nickel coating, good appearance and anti-corrosion.

4, Standard ISO 179, ASTM D6110, ISO 9854.

Plastic V notch impact sample 80*10*4mm Organic glass V notch impact sample 80*10*4mm

| Model | XJJ-5 | XJJ-50 |

| Impact energy | 1J, 2J, 4J, 5J | 7.5J, 15J, 25J, 50J |

| Impact speed | 2.9m/s | 3.8m/s |

| Pendulum center to specimen center distance | 221mm | 380mm |

| Pendulum initial angle | 160° | 160° |

| Supporting blade angle radius | R=1mm | |

| Supporting blade included angle | 30° | |

| Impact blade angle radius | R=2mm | |

| Specimen span | 40,60,70,95(mm) | |

| Display type | Dial analog display | |

| Specimen clamping type | Charpy | |

| Standard Accessories | Loadframe, pendulum(1J, 2J 4J, 5J), supporting vice jaws, specimen centering plate, spanner, manual etc. | Loadframe, pendulum(7.5J, 15J, 25J, 50J), moving supporting base, specimen centering plate, spanner, manual etc. |

Loadframe,

pendulum,

supporting vice jaws,

specimen centering plate,

spanner,

manual etc.

ISO 179: “Plastics -- Determination of Charpy impact properties”

ASTM D6110: “Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics”

ISO 180: “Plastics -- Determination of Izod impact strength”

ASTM D256: “Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics”

ISO 9854: “Thermoplastics pipes for the transport of fluids -- Determination of pendulum impact strength by the Charpy method”

ISO 8256: "Plastic Stretch Impact Intensity Determination" (method A)

ASTM D1822: "Plastic And Electric insulation Material Stretch Impact Performance test Method".