- Universal testing machine

- Fixtures

- Medical/Biomedical device

- Vehicles motorcycle

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

Adhesion strength 90 degree peeling test fixture. Peel Strength Testing

Testing the peel strength of bonded materials is one way to evaluate their adhesiveness. The peel strength is determined by applying a constant shear stress to the materials and calculating the resulting force multiplied by the bond surface width. Testing typically entails separating either two bonded flexible materials or a single bonded flexible material affixed to a stiff substrate.

Tape, adhesives, and flexible substrates like rubber, films, biomaterials, consumables, medical packaging, and more are often subjected to peel strength tests to describe their bonding strength. Various peel testing methods are available for a variety of materials.

Methods for evaluating peels

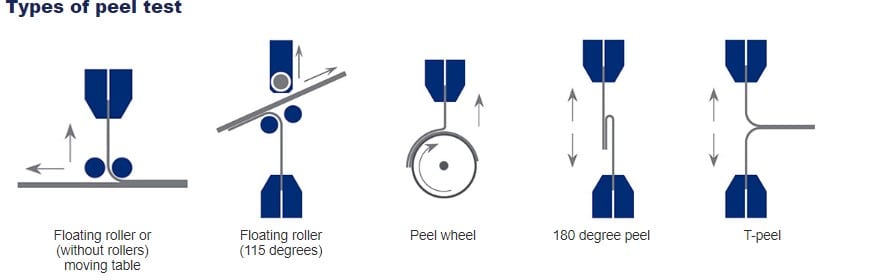

Peel strength testing is one of a kind since there are so many different kinds, and yet the vast majority can be evaluated with just a single universal testing machine. The most typical varieties of peel tests are:

180°-peel

The 180-degree peel test quantifies the force required to peel apart bonded materials at a right angle to the bond. It can be used to examine the binding between a flexible material and a hard substrate.

90°-peel

The 90-degree peel test is a method for calculating the unit force required to tear apart bound materials at a 90-degree angle. It can be used to examine the binding between a flexible material and a hard substrate.

1. Specification of sample backing plate: 200*60*3mm

2. The sample can be clamped: 60*5mm

3. Connecting Pin: Diameter 12mm

4. Connection shank: Diameter 30mm

ISO 29862 Self adhesive tapes – Determination of peel adhesion properties

ASTM D3330 Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

EN 1939 Peel adhesion properties of self-adhesive tapes

JIS Z0237 Self adhesive tapes-Determination of peel adhesion properties

PSTC 101 Peel Adhesion Test Method

Global links

Global links