- Universal testing machine

- Fixtures

- Medical/Biomedical device

- Vehicles motorcycle

- Compression/Flexural test

- Hardness tester

- Impact testing machine

- Torsion testing machine

- Abrasion & wear tester

- Plastic & Pipe testing

- Tensiometer / Goniometer

- Erichsen cupping tester

- Other Testing Equipment

- Grinding & polishing machine

- Spring testing machine

- Introduction

- Specification

- Accessories

- Standard

- LEAFLET & VIDEO

- Contact Us

Fatigue testing equipment is often used to determine how a material will perform over time and repeated use.

United Test offer the UTDS series Electronic Dynamic Universal Testing Machine/ Cyclic Testing Equipment widely used at material and components, parts dynamic mechanical property test, include tension, compression, low cycling test, match with high-low temperature chamber can execute the temperature test.

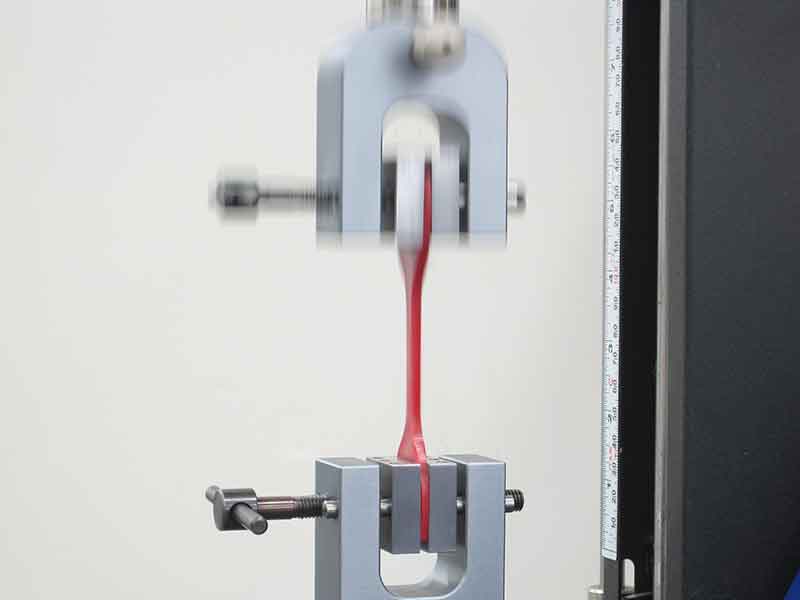

Fatigue testing on an elastomer

Feature:

1, One control chanel, with load, displacement, deformation three close-loop control, these three control type smoothly switch.

2, Max. close-loop data flash frequency is 6Khz;

3, Controller A/D, D/A resolution is 16 bit, signal generate frequency is 0.001Hz~ 50HZ;

4, Signal generate waveform include sine wave, triangular wave, quare wave, sawtooth wave etc.,;

5, Two levels servo valve driving unit used to drive the servo valve, remote hydraulic pump used to remote control the hydraulic pump station;

Cyclic test EN 397 Compression Testing Industrial Safety Helmets

| Max. static load | ±5KN Accuracy ±1% |

| Max. dynamic load | ±1kN |

| Dynamic fluctuation | Less than ±1%FS |

| Actuator max. stroke | ±100mm |

| Frequency | 0.01~15Hz |

| Control mode | Load, displacement, deformation |

| Main test waveform | sine wave, triangular wave, quare wave, sawtooth wave etc., |

| Max. test space | 550mm (include test fixture) |

| Test width | 430mm |

| Dimensions | 785*620*1650mm |

| Standard Power | 220/110V, 50/60HZ, 1 phase |

| Working system | MS Win7 / Win10 |

| High Stiffness Frame | 1 set |

| Servo liner actuator | 1 set |

| Servo driver | 1 set |

| Loadcell: | 1 set |

| LVDT (liner displacement sensor) | 1 set |

| Test fixture (quote and design according details test sample). | 1 set |

| Fully digital servo controller | 1 set |

| Professional testing software | 1 set |

| Computer | 1 set |

| Printer | 1 set |

| Documents (Manual, packing list, certificate) | |

Comply with different standards such as ASTM F2606, ASTM F2516, ASTM F2267, ASTM F384, EN 397 etc.,.